EU Legislators to outlaw use of Needless Mercury

EU legislators have started the process to outlaw the use of needless mercury in dental amalgam. In January members of the European parliament also voted

Unprocessed mercury can now no longer be sold or disposed of in Australia, putting extra pressure on the many industries who extract or who have mercury as a by-product of their production processes, particularly in the oil, gas, and mining industries.

Recognizing the need to uphold the spirit of the Minamata convention and the stringent EU protocols with respect to a traceable solution for surplus mercury, Ecocycle have committed to the latest European technology with a new mobile encapsulating unit being commissioned and operational in early 2024.

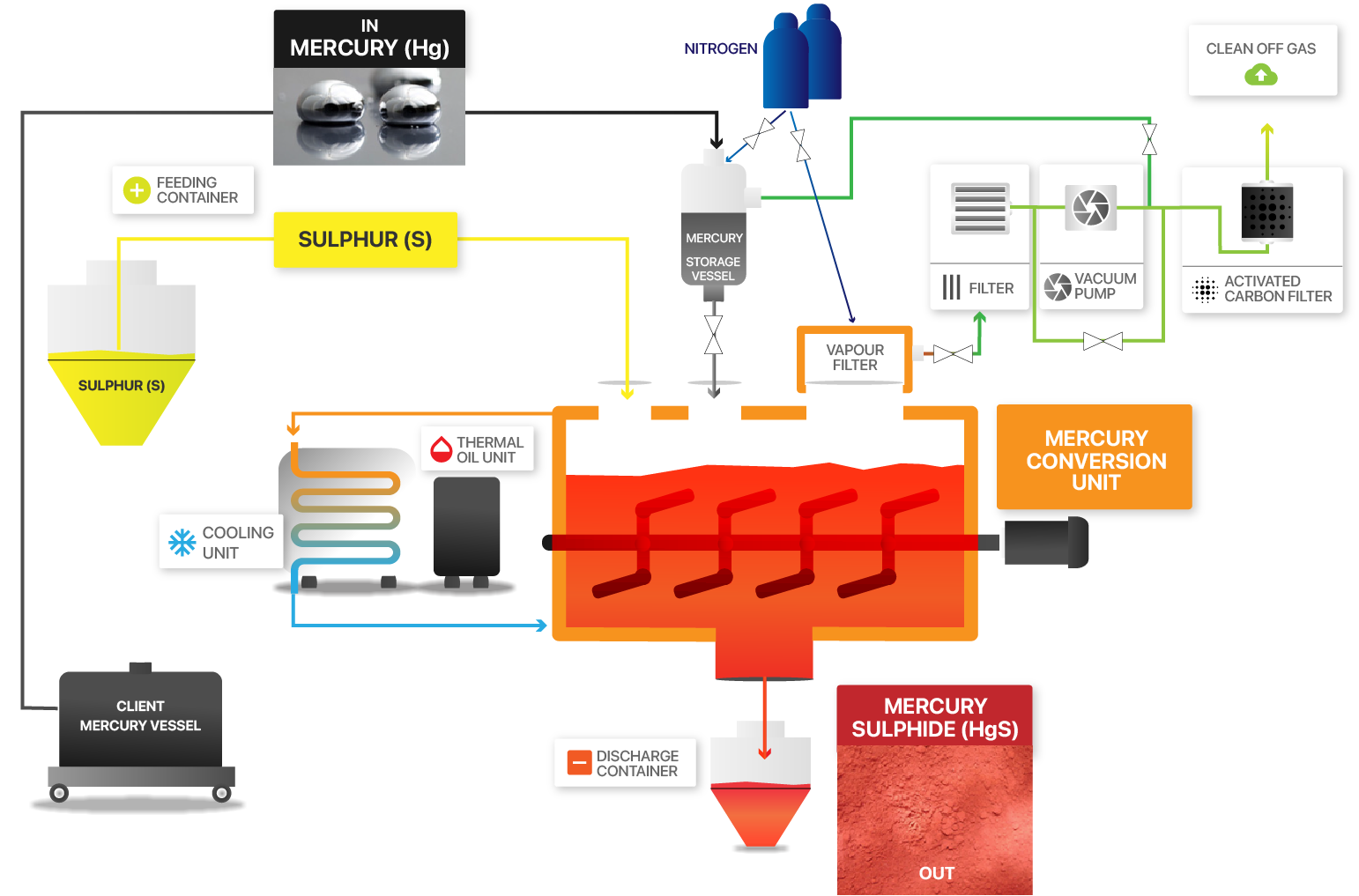

Ecocycle will process the recovered mercury by treating it with sulphur in a heated vacuum environment. In this inert atmosphere liquid mercury and sulphur powder react in a safe and hermetically closed reactor. Continuous intensive mixing during the process ensures complete stoichiometric reaction of mercury and sulphur. The resulting mercury sulphide becomes a material, that can then be safely disposed of.

The new technology from European leader, Econ Industries, pioneered a traceable and economic solution for mercury retirement. The technology processes the recovered mercury, treating it with Sulphur in a heated vacuum environment. In this inert atmosphere liquid mercury and Sulphur powder react in a safe and hermetically closed reactor. Continuous intensive mixing during the process ensures complete stoichiometric reaction of mercury and Sulphur. The resulting mercury sulphide becomes a material, that can then be safely disposed of.

EU legislators have started the process to outlaw the use of needless mercury in dental amalgam. In January members of the European parliament also voted

With the need for energy efficient-lighting solutions increasing, the recycling of old LEDs and mercury bearing lights needs more focus. Zoltan Sekula, of e-waste recycler

October 2023 marked the 10th anniversary of the adoption of the Minamata Convention. A deal that showed the importance of international diplomacy when it comes

With the introduction of the Minamata convention there is a need to understand the global changes in supply and demand for mercury. Current estimates suggest

Managing mercury risk is an important issue for many Australian industrial companies. Mercury causes very harmful and lasting health impacts due to its toxicity. The

"*" indicates required fields

Contact us on 1300 32 62 92 or get in touch with us online.

© Copyright Ecocycle 2022. All rights reserved. | Site by The Faith Agency